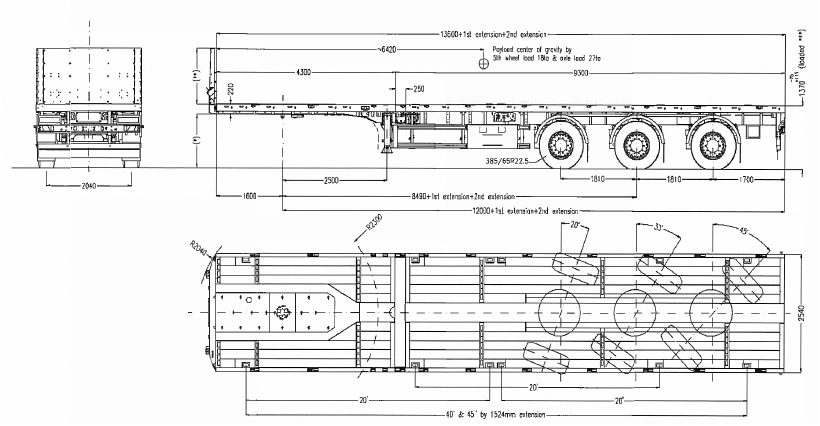

Maxtrailer 3-axle-tele-platform-trailer (double telescopic) MAX210

Maxtrailer 3-axle-tele-platform-trailer (double telescopic) MAX210, forced steering Specifications| Total weight | approx. 48.000 kg |

| Payload 80km/h | approx. 37.000 kg |

| Empty load | approx. 11.000 kg |

| telescopiec / extendable | approx. 15.400 mm |

| Gooseneck length | |

| Vehicle width | approx. 2.540 mm |

| Coupling height | approx. 1.200 mm |

| Loading height | approx. 1.370 mm |

| Loading length | approx. 13.600 mm |

| Manufacturer | MaxTrailer |

| Type | plateau trailer |

| Axles | 3 |

| Steering | Forced steering |

rent- or sales price on demand by contact person:

Ralf Meissner

+49 (0) 231 72 08 40 - 13

Sascha Funke

+ 49 (0) 231 72 08 40 - 12

Lennart Hinz

+ 49 (0) 231 72 08 40 - 19

Lara Lorenz

+ 49 (0) 231 72 08 40 - 21